Vibration monitoring we offer the latest online vibration monitoring solutions to keep rotating equipment running smoothly and maintain plant safety.

Vibration monitoring system ppt.

An in depth machinery vibration ppt series from 4 day machine vibration training course titled fundamentals of machinery and equipment vibrations and vibration control.

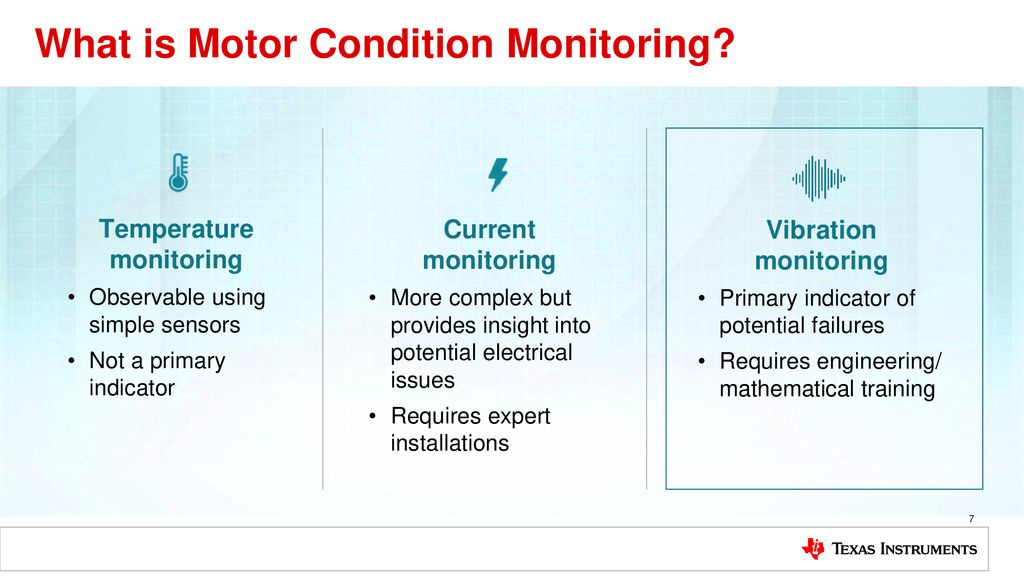

While all machinery vibrates monitoring excess vibration in rotating equipment is key to early identification of asset issues.

With economical online condition monitoring systems organizations can take advantage of the benefits of online condition monitoring at a user friendly price.

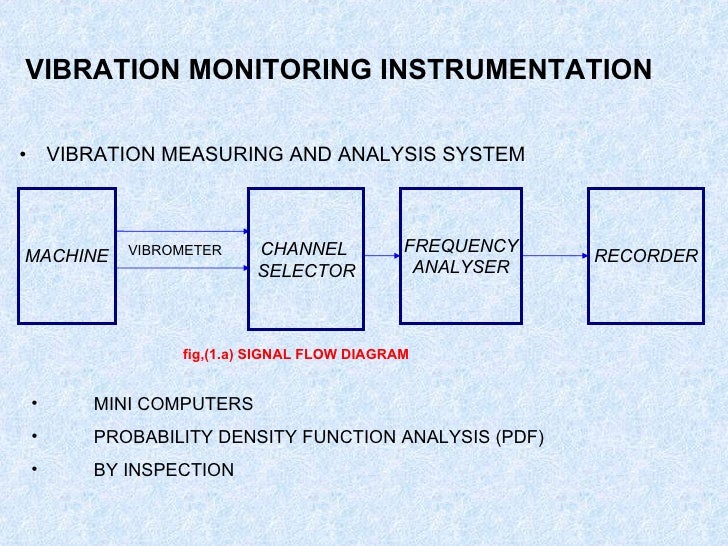

Vibration monitoring devices use accelerometers to measure changes in amplitude frequency and intensity of forces that damage rotating equipment.

Mounting and dismounting.

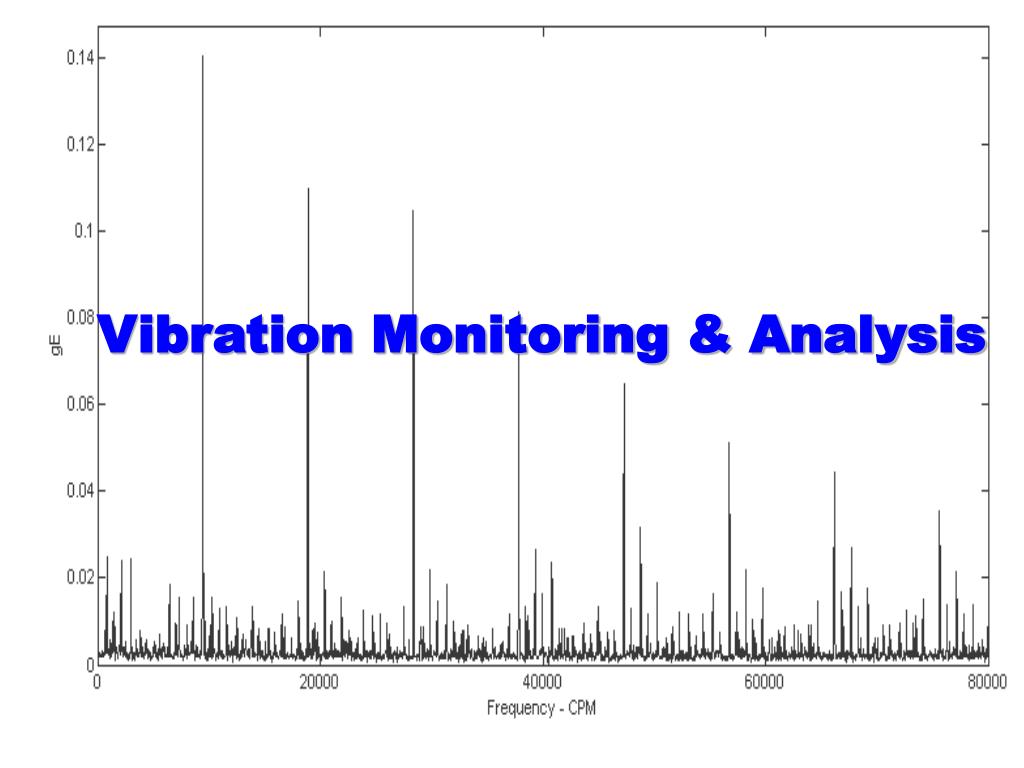

Switching between time and frequency is a common tool used for analysis.

Vibration analysis and diagnostics.

The adobe flash plugin is needed to view this content.

What is vibration.

The vibration powerpoint set has 627 powerpoint slides with detailed content on machinery vibration analysis bearing vibration condition monitoring industrial equipment.

Remove this presentation flag as inappropriate i don t like this i like this remember as a favorite.

Get the plugin now.

Condition monitoring system installations.

Because the frequency spectrum is derived from the data in.

Beginning vibration 2 introduction understanding the basics and fundamentals of vibration analysis are very important in forming a solid background to analyze problems on rotating machinery.

Online vibration monitoring is an essential tool for predictive maintenance pdm enabling asset owners to maximize productivity and minimize downtime while increasing worker safety.

Powerpoint ppt presentation free to view.

Remanufacturing and customization.

Vibration monitoring can be defined as the monitoring of the rotary equipment pumps compressors turbines fans etc using a set of tools to find out equipment health continuously or at a predetermined interval that can develop vibration or equipment malfunction in the system.

Condition monitoring system market estimated to exhibit 9 5 cagr through 2029 based on technique the condition monitoring system market is segmented into vibration analysis corrosion monitoring infrared thermography ultrasound testing motor condition monitoring and oil analysis.

Spindle repair and rebuild.

Our systems provide plantwide analysis and diagnosis to reduce downtime and unplanned shutdowns.