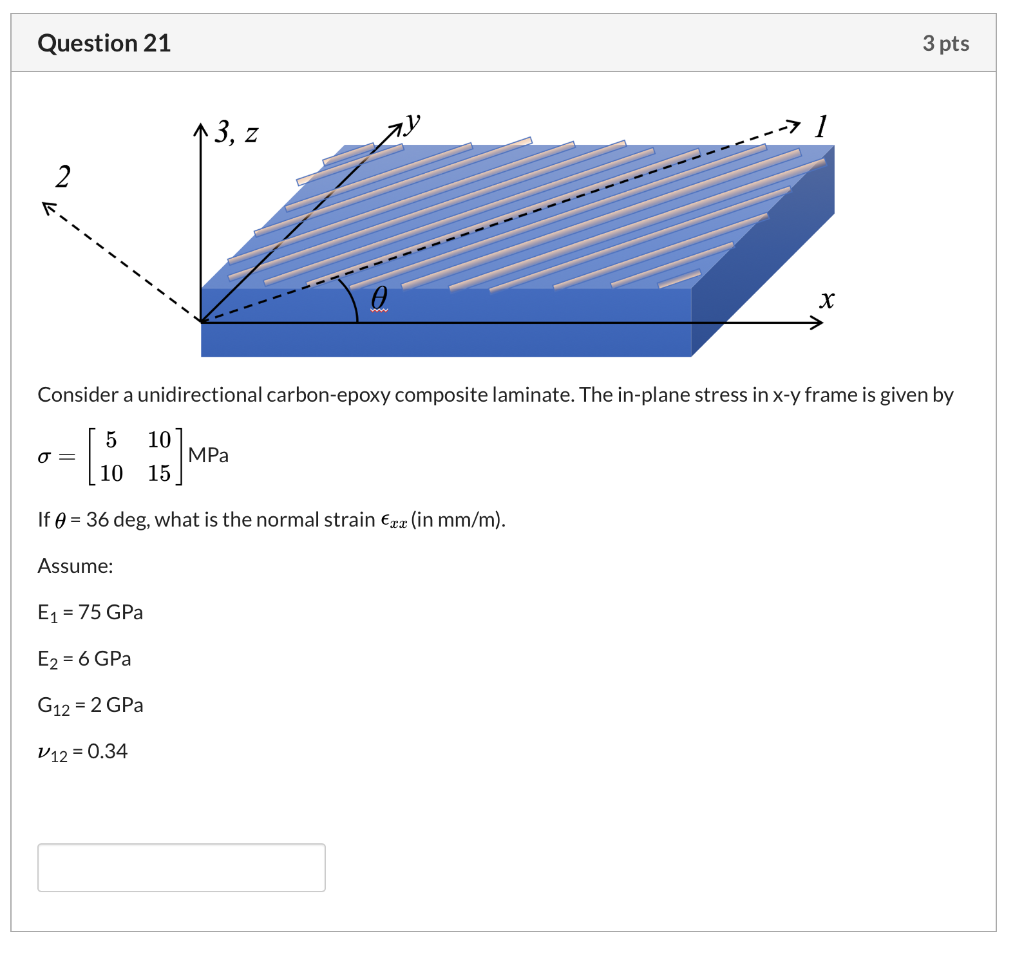

The lamina ply elastic properties are defined by the modulus in the fiber direction e1 the transverse modulus e2 the major poisson s ratio 12 and the shear modulus g12 the minor poisson s ratio 21 2 12 1 ee is also used in the.

Unidirectional composite laminate images.

Over the past few decades fiber reinforced plastics frp have been developed as the foremost material for products in.

Predetermined aging intervals of 24 120 240 and 720 h were used to investigate the effect of hot water absorption on the mechanical performance and weight changes of the unidirectional composite.

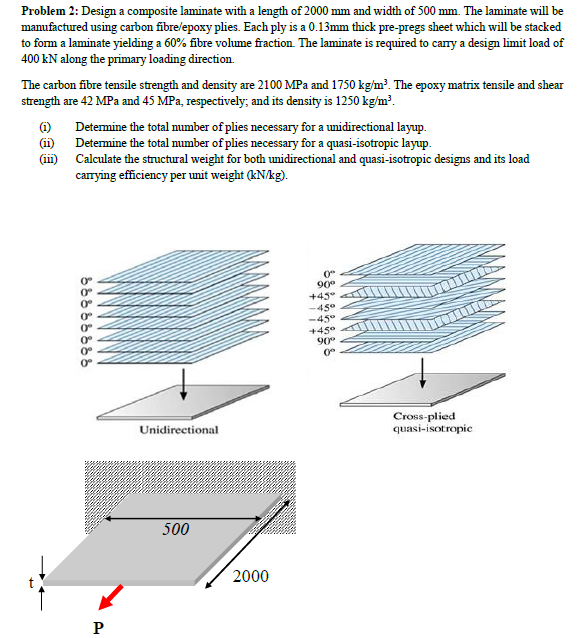

Basics of composite laminates using lamination parameters elastic constants for a unidirectional lamina.

This results in the highest possible fibre properties from a fabric in composite component construction.

The environmental fluids examined in this study were distilled and saline water under different temperatures and salt concentrations.

Again the simple formula in the equation above was used to obtain a factor for calculating the unidirectional composite strength from the measured cross ply laminate strength.

Dcb tests carbon fiber fracture toughness interlaminar delamination.

This factor has come to be called the back out factor since the unidirectional composite strength is backed out of the cross ply strength experimental data.

True unidirectional fabrics offer the ability to place fibre in the component exactly where it is required and in the optimum quantity no more or less than required.

To investigate the absorption behavior of different constituents of polymeric composite various tests were conducted on fibers pure cured resin unidirectional composite specimens and laminated composites.

To extend the fatigue master curve to predict the braided composite laminate tensile tensile compressive compressive and tensile compressive fatigue experiments are carried out in this paper.

The curved laminate failed unstably by delaminations developing around the curved region of the laminate at different depths through the thickness until virtually all bending stiffness was lost.

Fatigue lives of composite laminates made by unidirectional carbon and glass fiber reinforced composite are predicted by the proposed method.

Unidirectional composite laminates are tested to get the mechanical properties of t700 epoxy and tubular composite laminates are tested to get the tension torsion biaxial mechanical properties of composite laminates.

Similarly water absorption tests of pure nylon 6 and cf nylon 6 laminates were performed to determine the water absorption history.

The quasi maximal distortion angle is from 3 to 5 for different patterns and the analogous measurement was reported by chang et al.

As well as this ud fibres are straight and uncrimped.

Machine using a laminated composite carbon fiber oriented unidirectional.